Introduction:

Introduction:

Ville Puoskari from Finland ordered one of our telescope primary mirrors. We supplied the mirror of high quality and on time to Ville. Here is what he mentions about our customer service and the special mirror.

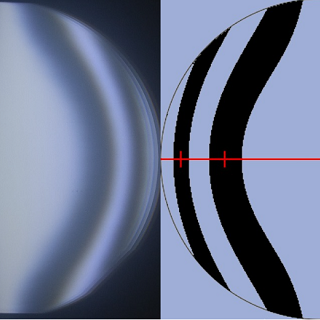

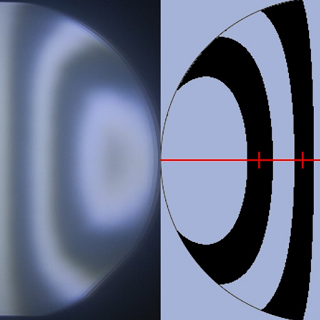

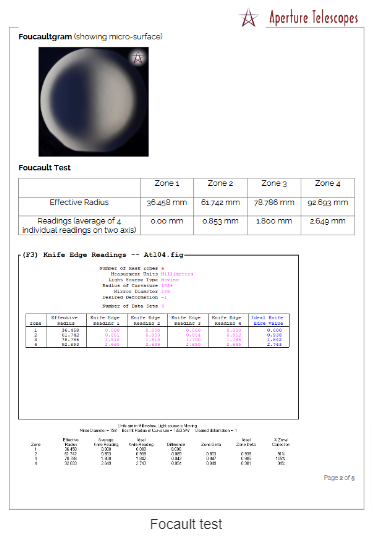

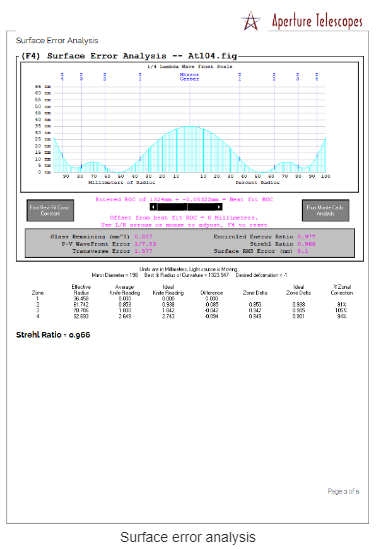

Ever since I have built the first version of my travel telescope with a 3D printer – I have had a feeling I could make a larger aperture scope for my astronomical adventures. With larger aperture comes the inevitable problem of focal length – a 200mm f/5 telescope is almost a meter long! But what if you would go with a faster optical system? Well there is an idea! Que a long but fruitful conversation to India and the heart of this project is born at the hands of a master optician of Aperture telescopes. For a custom made mirror I wanted to go all in and boy did they not disappoint. The primary mirror is 200mm diameter f/3.3 light bucket with a measured Strehl ratio of 0.966!

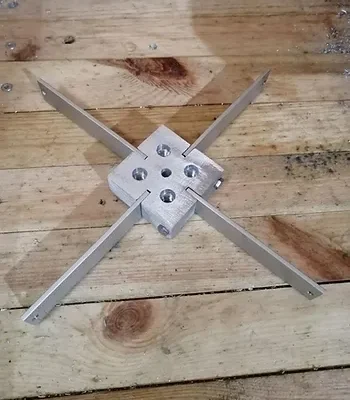

With such a great mirror comes the need for a very good secondary mirror too. My first purchase of a 90mm diameter Hubble Optics secondary from Germany came in a million pieces due to poor packaging, although I got a full refund on that I have not been able to source another one yet in EU. Speaking of secondary mirrors – I have made some progress on the secondary mirror spider – the first iteration was 3D printed with an aluminum central piece for bolts. Then I had an idea that I could make the entire assembly if I just had a proper milling machine – or that was at least the excuse I gave myself (and the wife!) to buy a milling machine.

It remains to be seen which of these is a better solution, I’m keen to test them out for potential flexures once the OTA is completed. Stay tuned for part two!

Ajay Talwar, your article *Go Fast, or Go Home! – Part I* (July 4, 2024) offers an engaging glimpse into Ville Puoskari’s ambitious project with your custom-made 200mm f/3.3 primary mirror from Aperture Telescopes. Your introduction effectively showcases your company’s commitment to quality and timely delivery, as evidenced by Ville’s satisfaction. His pursuit of a faster optical system—yielding a compact yet powerful scope—highlights an innovative approach to telescope design, and the mirror’s impressive Strehl ratio of 0.966 speaks to the precision craftsmanship involved.

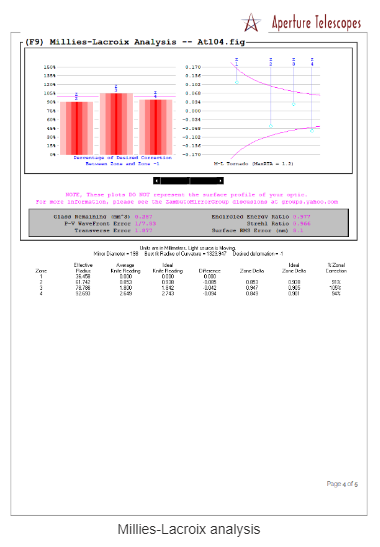

The technical details, from the Ronchi and Foucault tests to the surface error and Millies-Lacroix analyses, provide a robust validation of the mirror’s optical quality, appealing to enthusiasts who value such metrics. Ville’s challenges with sourcing a secondary mirror and his shift to milling his own spider assembly add a practical, relatable dimension to the narrative, reflecting the iterative nature of DIY astronomy projects. While not mentioned, a Dobsonian mount could complement this fast mirror’s design, offering stability and ease for a travel scope. Your piece sets a strong foundation for Part II, promising further insights into this high-performance build. Well-executed and technically sound.

This is a fantastic read! Villes dedication to astronomical adventures is truly inspiring, and his journey from a 3D printed travel scope to a monster f/3.3 beast is absolutely commendable. The quest for that perfect, custom mirror and the subsequent adventures with secondary mirrors and justifying a milling machine are hilarious! Its a testament to the passion that drives us all. Cant wait for Part Two to see if that spider works or if the OTA ends up being a flexible mess! Great stuff, Ajay.MIM